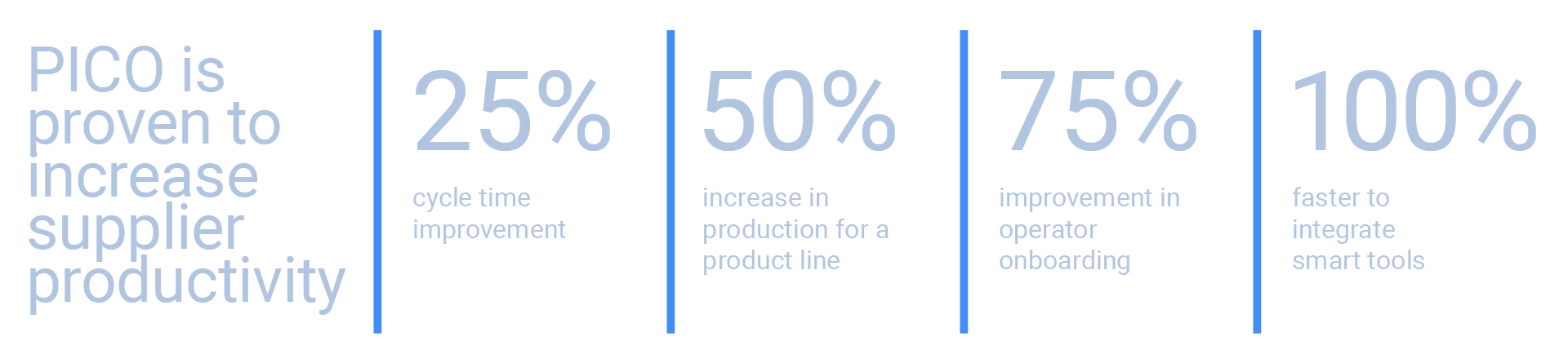

Reduce risk

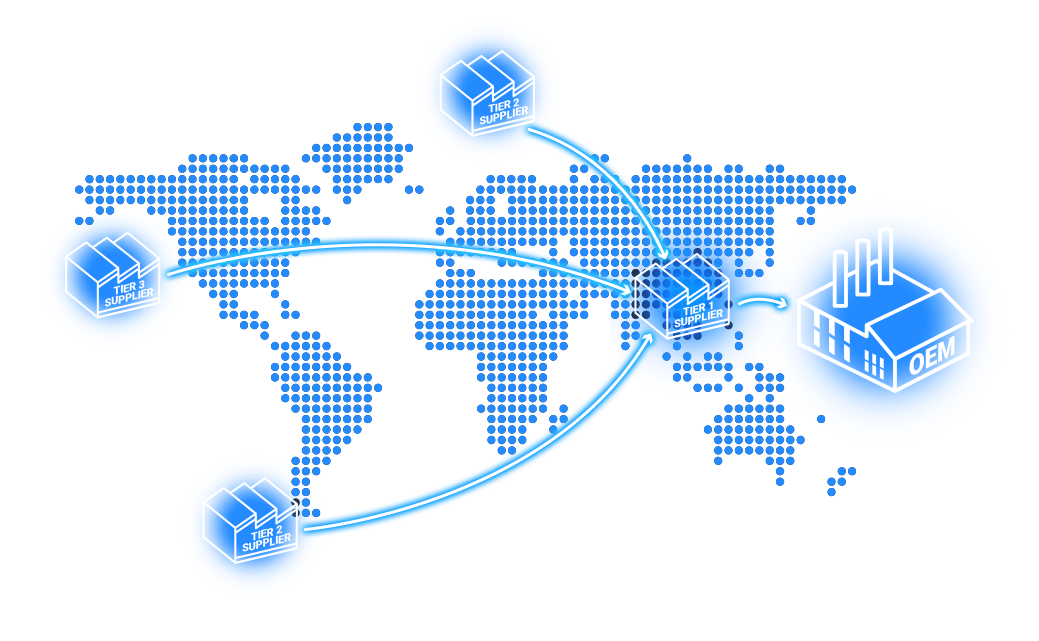

Real-time visibility into supplier processes allows for proactive management and quicker response time to production or quality issues.

Real-time visibility into supplier processes allows for proactive management and quicker response time to production or quality issues.

Communicate data instantly and accurately across the supply chain to address inefficiencies, defects, and bottlenecks.

Track resource consumption, labor, and other KPIs to minimize waste and drive down the cost of production.

Make data-driven decisions to help improve operating efficiencies and profit across the supply chain.

Use Cases |

For The OEM |

For The Supplier |

|---|---|---|

| Real-time progress tracking | Track parts as they’re handed off from supplier to supplier, and gain insight into the expected quantity and arrival time at your factory. | See which parts are in progress and how their KPIs are tracking, and which parts are ready to ship. |

| Alerting on quality issues | Mark nonconforming parts and flag for supplier review. | See parts flagged by the OEM to quickly begin root cause analysis. |

| Traceability from start-to-finish | Analyze the complete history of underperforming parts and collaborate with suppliers on process and design improvements. | Trace parts through the supply chain to understand consumption rates to optimize production. |

| Predictive analytics | Manage risk and maximize production through real-time analytics. | Identify process and quality issues to eliminate downtime and optimize output. |

.png)