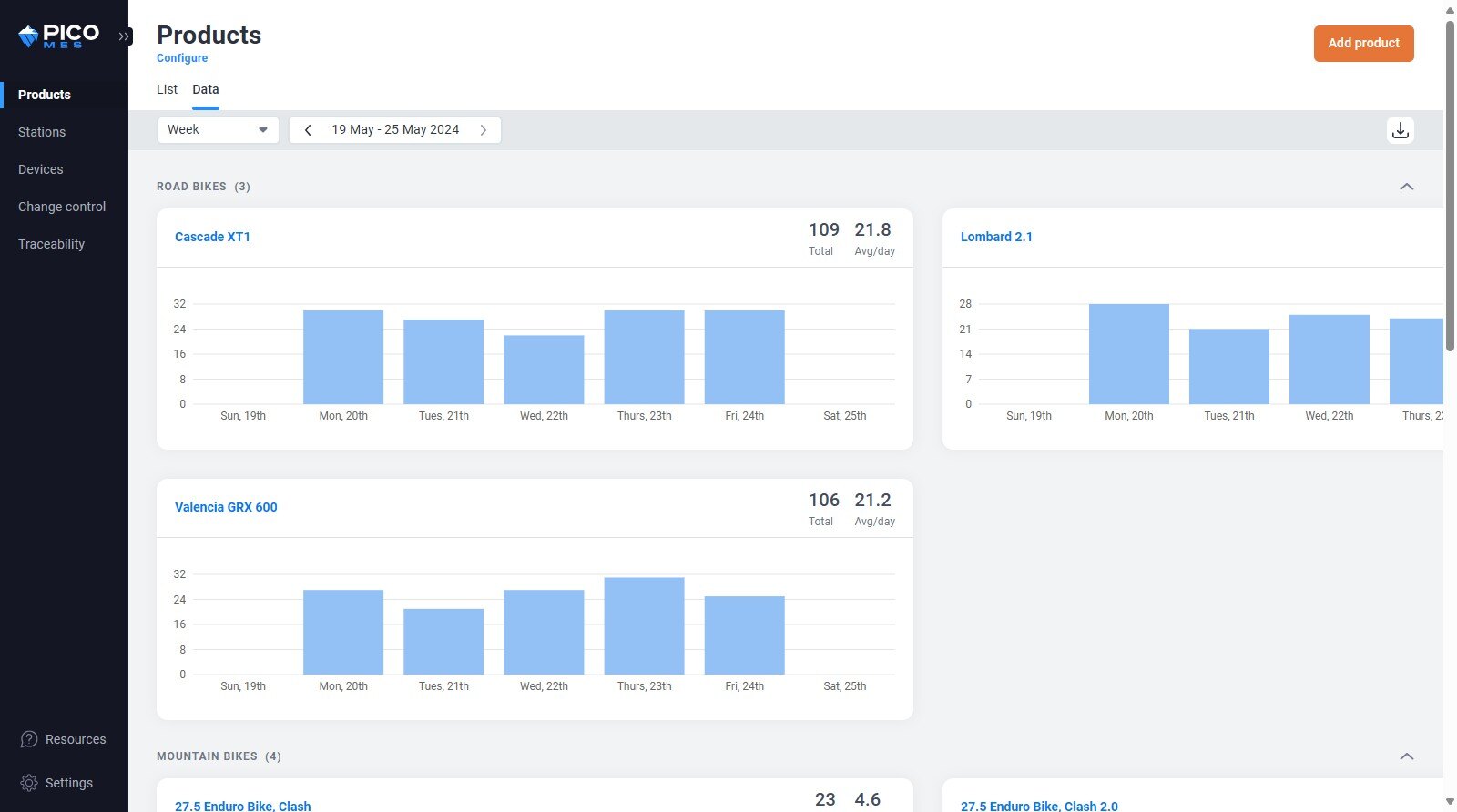

Manual data capture takes too long and leads to errors. PICO provides accurate real-time production data to help drive continuous improvement.

High-quality data

Measurements and results are checked at the point of capture by integrating IoT tools.

Manual data capture takes too long and leads to errors. PICO provides accurate real-time production data to help drive continuous improvement.

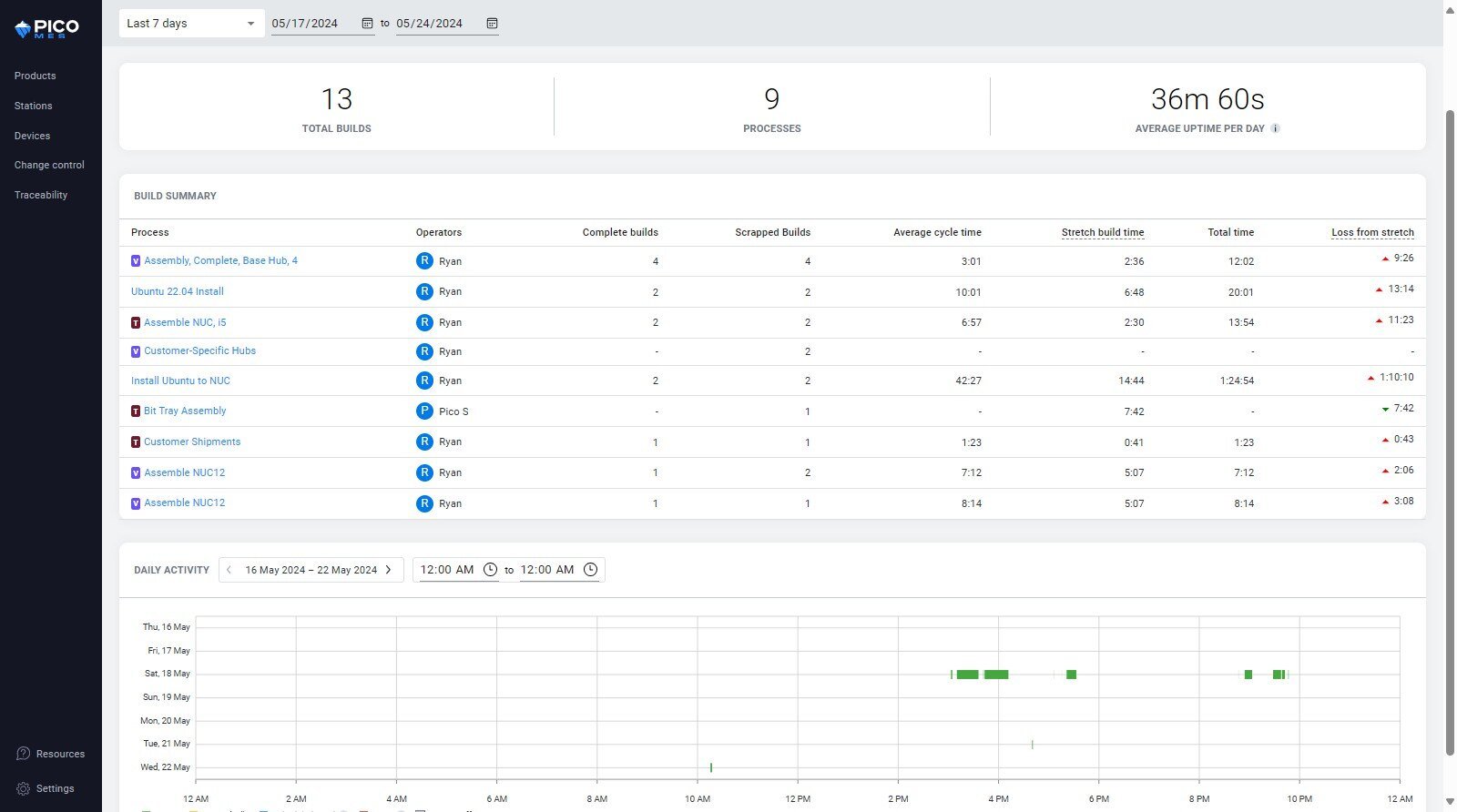

PICO makes answering the easy questions easy, and answering the complex questions possible. Our data capabilities eliminate the noise by automatically providing efficiency and productivity data at the process, station, and factory level. Take a self-guided tour to see for yourself.

Measurements and results are checked at the point of capture by integrating IoT tools.

Spend less time building reports and more time building with our pre-configured dashboards.

Seamlessly integrate with your BI tools for in-depth analytics on KPIs unique to your business.

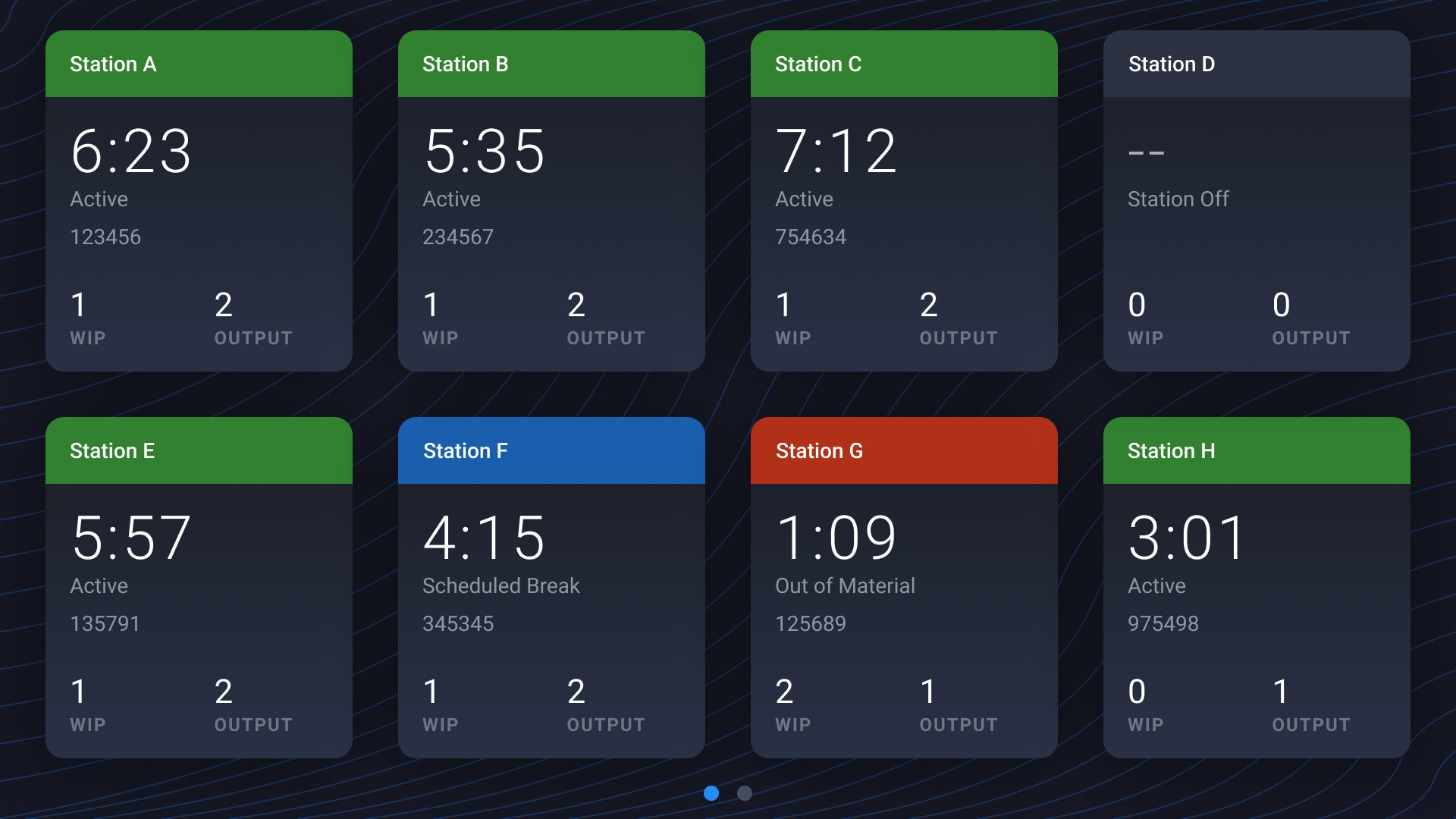

Monitor production across the factory floor and respond quickly to disruptions and bottlenecks.

PICO is designed to reduce the amount of time spent crunching spreadsheets, and maximize the time spent on continuous improvement. Learn more about the features that help you do just that.

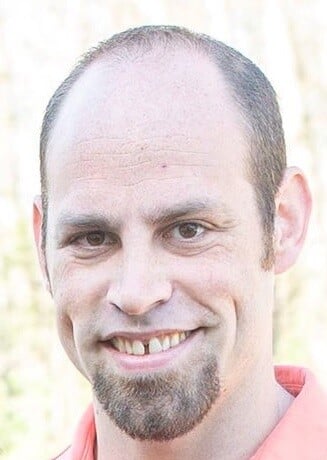

“I love it because there’s so much information from a time study standpoint and from having a feedback loop of how production is actually going on the floor. That used to be a completely foreign concept to us.”

Greg Whitt

Process Improvement Engineer

MORryde International

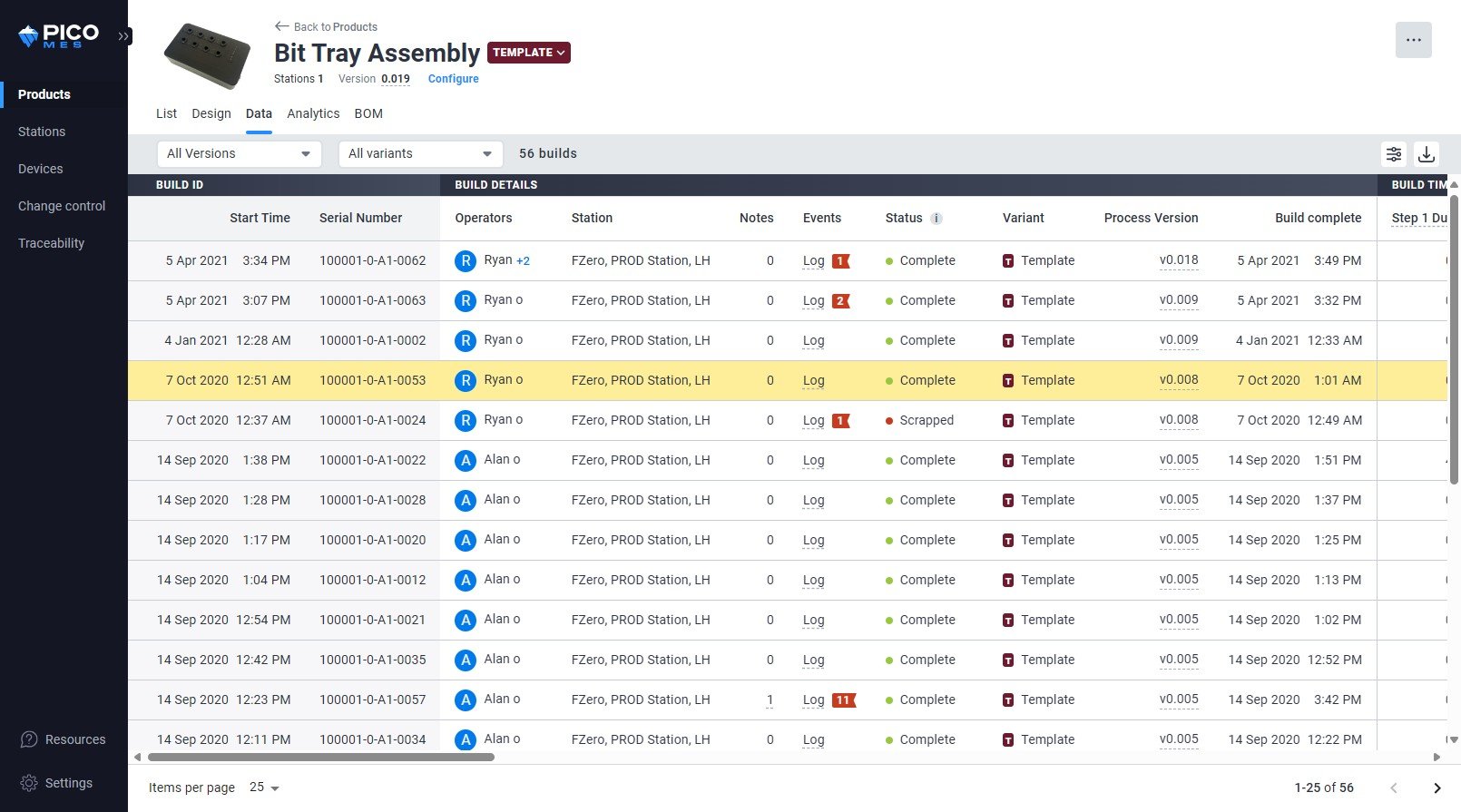

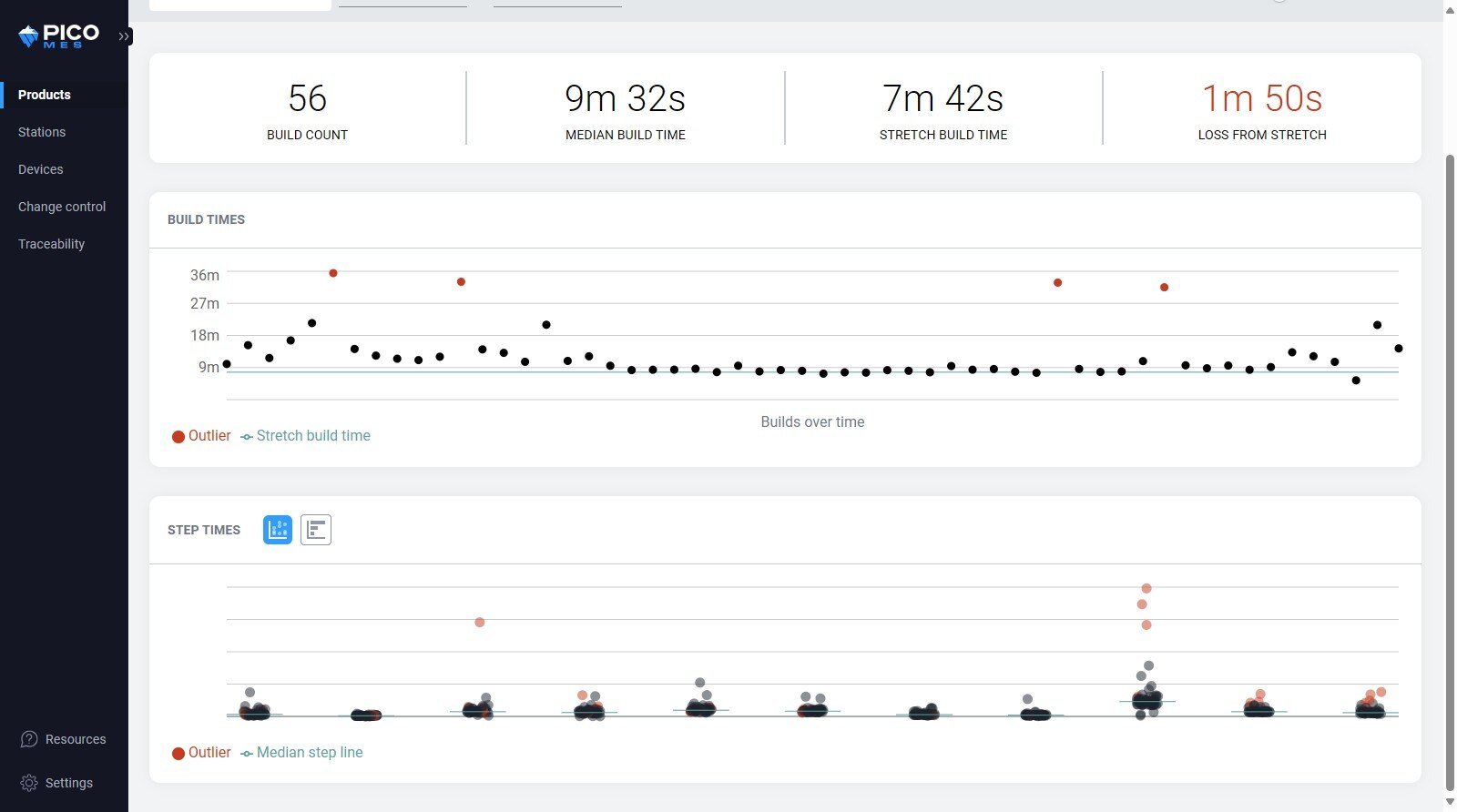

PICO provides real-time visibility into key metrics such as output per workstation, process durations, and individual build histories—making it easier to monitor efficiency and productivity across the shop floor.

PICO enhances data integrity by directly integrating with IoT tools at the point of capture, ensuring tool data and measurement results are reliable and structured for downstream analysis.

The platform offers live dashboards that monitor production rates, cycle times, step-level performance, and workstation throughput—helping manufacturing leaders be proactive, not reactive.

In addition to tool data, PICO captures metadata about the operator, station, process, and parts from every build. These comprehensive build records are instantly found in PICO by simply searching a serial number, part number, or work order, enabling full backwards traceability and a "digital product passport" for every part assembled.

PICO integrates seamlessly with your BI and reporting platforms—including Power BI, Tableau, HEX, Microsoft Excel, and Sigma—so you can further analyze your manufacturing data in your preferred analytics environment.

Step into the future of factory operations with Pico MES. Start your journey toward a more efficient, error-proof factory floor today.