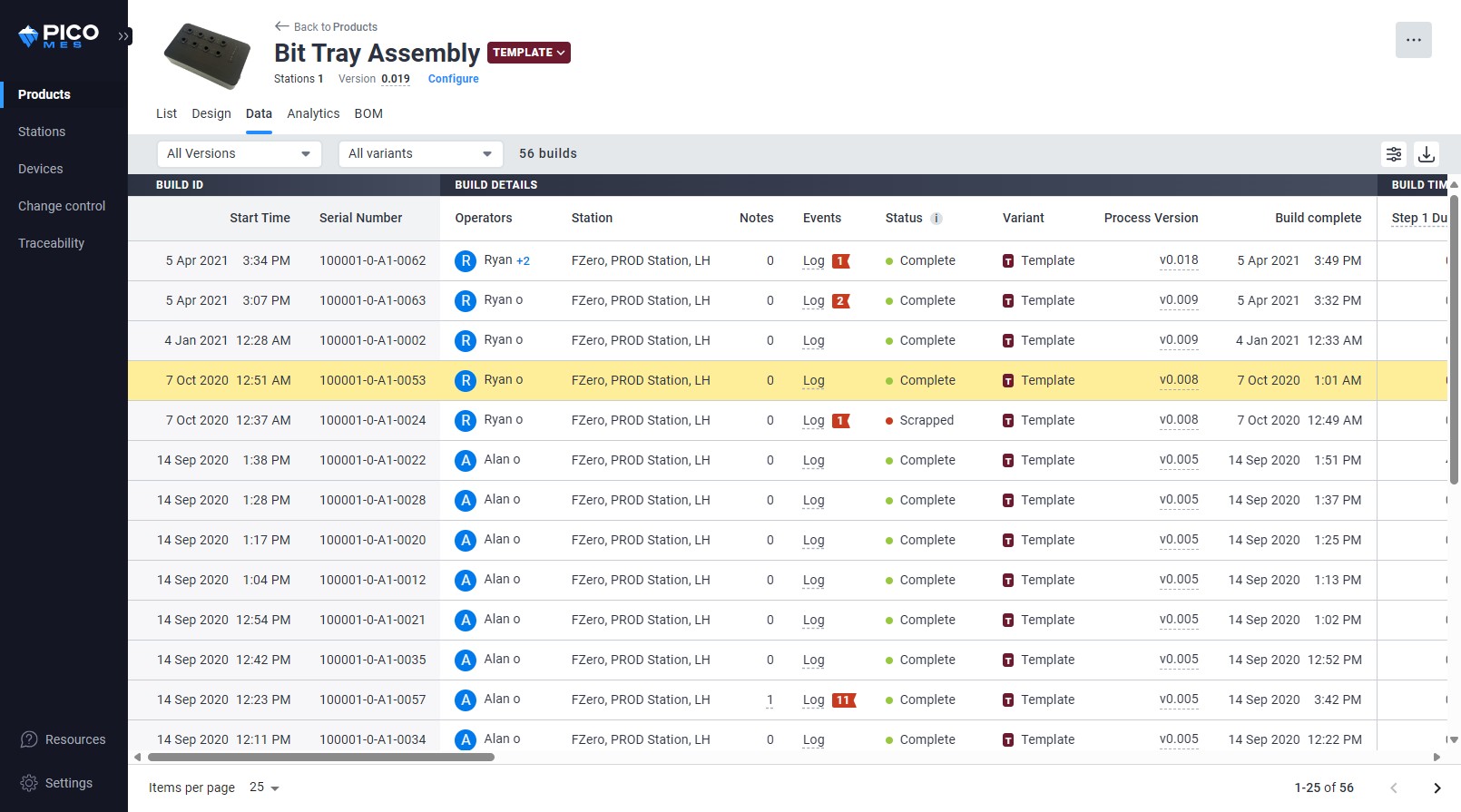

Enable Full Traceability

Migrating from cloud to on-premise deployment

An on-site deployment is available in the Essential plan. Setting up is easy - you just need a PICO server (Intel NUC) and Hub (edge device) that will run off your local network. The server is managed by PICO so you never have to worry about patches or software upgrades. Store your processes locally and back up to the cloud.

Integrate a barcode scanner for traceability

Connect your favorite barcode scanner to PICO and add a scanning action to your work instructions to quickly record part or serial numbers from your build. This feature replaces the need for a manual entry action and allows for quicker builds. You can also use connected scanners to quickly trace a part's build history by scanning its barcode.

Real-time visibility across the factory floor

Visualize your factory floor using our Visual Factory feature which allows you to digitally recreate your workstations as they exist on the shop floor. Create customized dashboards showing current status and progress at each station and display on monitors so you can monitor production and quickly respond to issues.

Manage operator training in the skills matrix

PICO's skills matrix helps supervisors manage each operator's credentials to ensure that they're building with the proper supervision. As operators reach new levels of training, update their status in the skills matrix to allow them to build unsupervised.

Want more features?

Upgrade to Professional to unlock more features:

- Full access to our library of 200+ no-code device integrations

- Machine tending dashboarding

- Hybrid cloud-local deployment