Human Error

Reduce operator errors stemming from unclear, outdated work instructions.

Efficiency gains and improved product quality are best achieved when manufacturers digitize their shop floor.

Operators rely on Google Docs, MS Word, MS PowerPoint, MS Excel, or plain old paper documents stuffed into dusty binders for their assembly instructions.

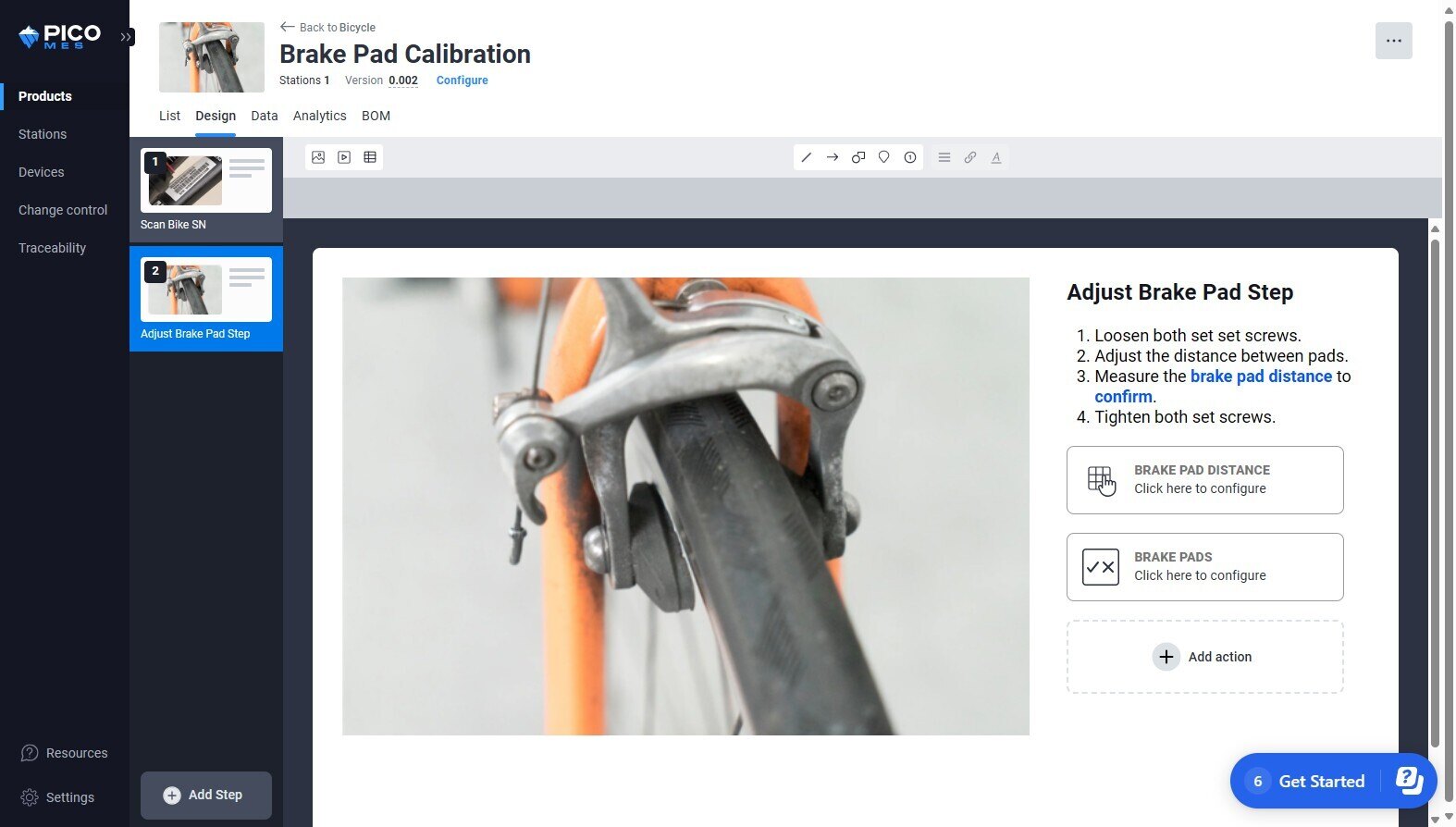

Digital work instructions complete with images, text, annotations, and hyperlinked media are easy to create and even easier to follow.

.png)

"PICO is the perfect trainer. It helps us create perfect products. We hand an operator a tablet, they follow instructions, and they don't make mistakes.”

Manufacturers use PICO to provide their workforce with detailed worker guidance, resulting in assemblies unaffected by human error.

Find out how one automotive supplier was able to leverage PICO to produce nearly 2,000 parts without any defects.

Maurice Stallard

Director of Engineering & Manufacturing

HJI Supply Chain Solutions

PICO digital work instructions are free, eliminating the cost barrier that typically stands in the way of factory digitization. Small manufacturers can begin to error-proof their assembly operations at no cost.

PICO digital work instructions can be implemented in the cloud or on-premise and is both SOC2 and ITAR compliant. No hardware or specialized IT resources to get started.

Creating digital work instructions in PICO is easy and uses similar features to those found in MS PowerPoint or Google Slides.

PICO worker guidance is designed to be readily available to operators when needed, while also being minimally disruptive. Customize the amount of interaction required between PICO and operators as they build.

#{ truncateText(item.metadescription) }