Human Error

Eliminate mistakes stemming from manual data entry and reporting.

Eliminate mistakes stemming from manual data entry and reporting.

Gain access to every part's complete build history.

Eliminate shop floor chaos caused by manual data entry. Connect your IoT (and non-IoT) tools to PICO to start automating data capture and build a home for your production data.

Manual data entry leads to lost records, errors, and inefficiencies—making it nearly impossible to trace quality issues, track inventory, or prepare for audits.

Integrated tools capture data automatically from every build, providing instant access to production insights and every part's build history.

"PICO starts paying for itself right out of the box. There is an immediate value-add with automated data collection and worker guidance."

Engineers reduce the burden of data collection and reporting by automating the process in PICO, so they can instead focus on improving production.

Find out how one automotive manufacturer leveraged no-code tool integrations and digital worker guidance to error-proof their assembly operations and increase output by 50% for one of their product lines.

Greg Whitt

Continuous Improvement Engineer

MORryde International

PICO's device library features 200+ commercially available tool integrations to choose from. We do all the integration work for free so you don't need to rely on additional costly hardware specialists.

Connect your integrated tools to digital work instructions to configure device settings according to each process and prompt quality checks as operators build.

.jpg?width=2000&name=1R6A2471%20(1).jpg)

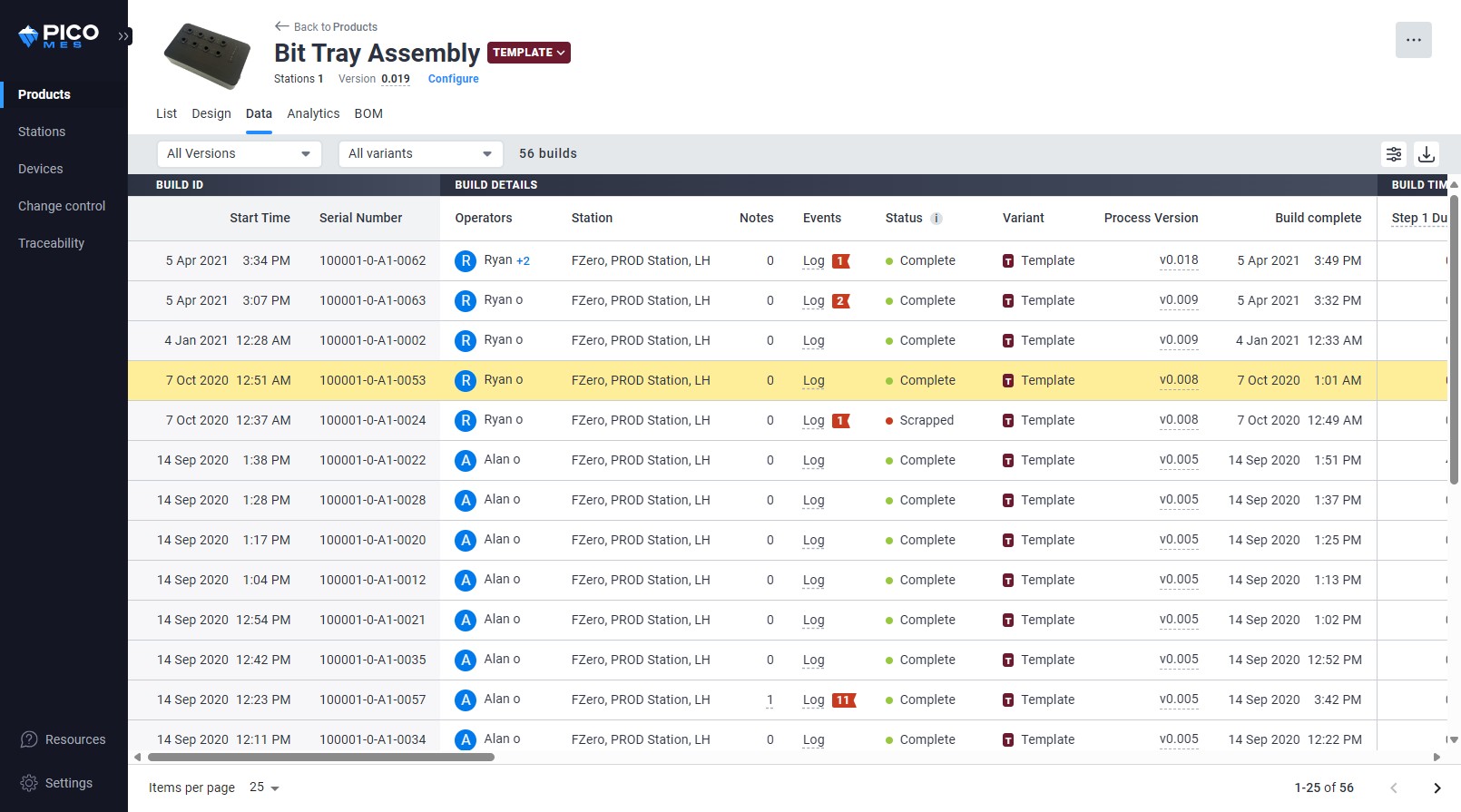

Tool data such as torque results and digital measurements are automatically captured and stored in a comprehensive build data table. Analytics dashboards instantly pull data for real-time visibility into your production.

Each part built using PICO is contextualized to an operator, workstation, and process, providing full backwards traceability to quickly analyze build history and easily identify causes of quality issues.

#{ truncateText(item.metadescription) }