#{ item.name }

#{ truncateText(item.metadescription) }

How do manufacturers manage work instructions for their high-mix, low-volume product assemblies? It’s highly likely that manufacturers producing multiple variations of the same end product without any sort of automation capability struggle to keep their processes separated and organized.

That’s why we created a process variant feature in our digital work instructions capability.

Steve Wishau, Head of Product at Pico MES, walks through how to set up and manage process variants.

Process variants (also referred to as configurations or options) describe any assembly process that produces a series of SKUs that tie back to a common product line. An example of this might be an engine that is available in different configurations.

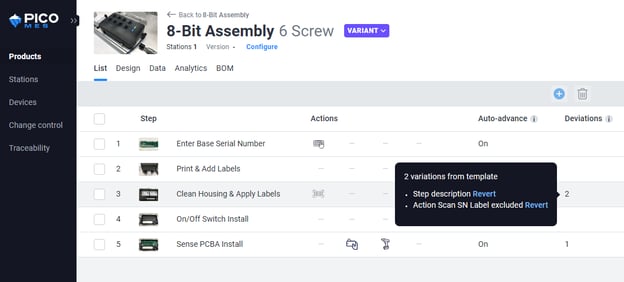

The processes used by operators to build these product variations mostly stay true to an original process (a template) but include deviations on select steps. For an assembly process that aims to produce a dozen different SKUs, you might end up with a dozen different sets of work instructions that all follow the same basic template.

Managing these work instructions separately can quickly become a headache for manufacturing engineers as making one change to the template means making the same change in several other places. Whether work instructions are managed digitally or on paper, the challenge remains the same - updating work instructions for process variants is a repetitive and time-consuming task that leaves factories at risk for errors.

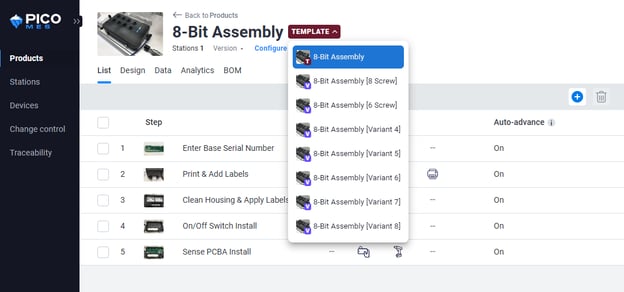

The process variant feature makes managing similar sets of work instructions easy by leveraging a template/ variant structure with linked and unlinked steps. Here’s how it works:

.png?width=624&height=285&name=simplifying-assemblies%20(Process%20Variants_1).png)

That’s it! If a change is made to the template process, it will be applied to all linked steps across all variants of that process. Any deviations in the process variants remain unchanged to reflect the differences in end product configuration.

Want to try it for yourself? Check out our self-guided demo.

There are several use cases for process variants. Here are some examples from our existing customers:

See more examples of how our customers have been able to simplify work instruction management and achieve significant engineering time savings in this video.

Our solution to managing a challenging environment of process variants is unique in that it makes updating digital work instructions easy, instantaneous, and non-repetitive. The feature is native to our digital work instructions function, whereas alternative solutions might rely on highly customized and complex logic streams that require greater skill and understanding to set up.

We’re on a mission to help American factories digitize their assembly processes, and we believe having an organized and streamlined way to manage process variants will help get our customers one step closer to an error-proofed factory.

Want to learn more? Check out these additional resources:

#{ truncateText(item.metadescription) }

Step into the future of factory operations with Pico MES. Start your journey toward a more efficient, error-proof factory floor today.